Getting your job ordered.

Step 1.

Decide what you need. We can help with advice on what garments and branding type is right for your job.

See our Services

Step 2.

Get a quote. Our instant estimate form on the front page will give you an idea of the pricing based on our most commonly requested items. However we supply hundreds of garments from dozens of suppliers so let us know what you need.

See Pricing

Step 3.

Send us your artwork and we proof. We require print ready Vector artwork, single colour artwork (when it doesn’t require a base ink, can be raster – this must be 300ppi at the size req), not all raster files work – SEE BELOW.

Step 4.

Approve the proof and supply final numbers.

Step 5.

We schedule, print your job and arrange a courier (unless you are collecting).

Step 6.

This is all in your hands now. Either hand out the apparel to your team, fulfill prorders or get selling or get your promo moving.

A quick note about pricing and sizes:

The pricebreak is based on total prints of a single design at one time. As such you can mix singlets, hoodies and tees and this would count towards the larger total.

However this also means you need to be aware of the sizing when designing, if your design needs to be one size on adults and one size on kids this would effectively double the setup fee and split the pricebreak quantity. We recommend working as large as possible on the smallest garment.

What we need from you

The below sections go into detail however the things we need are:

• Vector Artwork, we can send your artwork to be redrawn for a fee.

• Pantone Colour, numbers to match colours to.

• Desired Positioning and Sizing

We will then need your quantities and size break down and delivery address.

Vector Artwork

We require Vector Artwork to produce quality work.

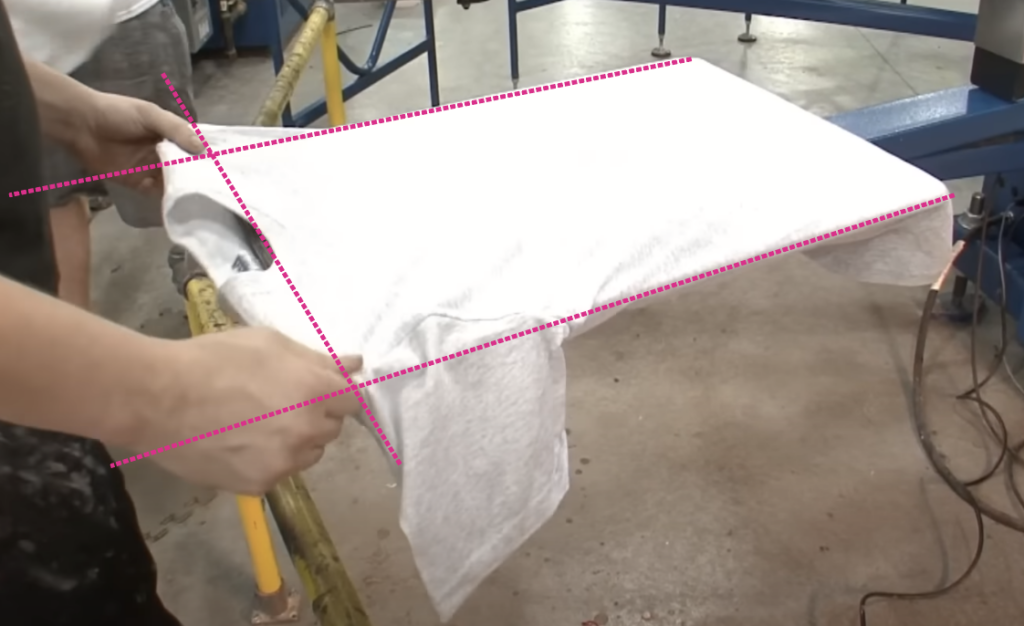

This image shows part of the story why we need Vector artwork – Quality – But not the whole thing. Vector artwork is generally made from scratch in Illustrator or Corel Draw.

Vector artwork allows us to resize, and select individual elements. This means colours separation is easier and we can make basic alterations without charging!

There are rare occasions where Raster Artwork is fine, however this is generally only for basic images and where the image is very high resolution (300ppi @ size required) and single colour – and without the need for Trapping (ie Black on White). Otherwise pixelation and other issues will likely occur – If you zoom in and it looks awful on screen, it will look awful when printed.

Most of the time you should aim to provide Vector Artwork . Preferably in a .pdf format. If you cannot supply this – check with any printers that may have printed Business Cards or Signs.

https://design.vectr.com/tutorials/what-are-vector-graphics/

https://artistshopshelp.threadless.com/article/787-vector-vs-raster

If you cannot supply required artwork format:

The first step is to Contact your marketing team or designer – generally speaking Branding Guide files will have vector artwork in them.

Vector artwork is part of the curriculum for any design course – outside of web only courses (though this is changing with SVGs growing in popularity) so while all design agencies will understand and produce primarily in Vector (aside from photos etc) your web designer may only have a basic understanding of print.

If you are having issues contacting your designer we can send art off for Redrawing for a fee – Otherwise services such as UpWork, Fiverr and Freelancer have services to prep your artwork.

Pantone Colours

Every computer screen is different, to get around this we match to the Pantone Colour Matching System (Solid Colours).

We match to Pantone Colours, without these being provided we can approximate to screen, any variance or issues arising from this on the first or further runs is the at the clients risk.

It is likely your designer has these on file!

CMYK

Even if you do not know your Pantone Colour it is best if you work in CMYK. Full Colour images should always be set to CMYK.

RGB is for web design and things that will be seen on screens, it is a backlit system and produces colours that cannot be achieved through any form of conventional printing.

We will provide a proof on your requested garments before we go to print, your job will not be printed or scheduled until this is approved.

Vector Artwork

We prefer vector artwork as this allows us to resize to better digitise your artwork – However the process is different for embroidery as it needs to be Digitised.

However this is not essential, a high res Raster file is fine for us to have artwork digitised from.

Madeira Thread Colour

Every computer screen is different, to get around this we match to the Madeira Thread system.

Your designer might have this one file.

or Pantone Solid C/U number

If we need to set a Madeira thread colour. Every computer screen is different, to get around this we match to the Pantone Colour Matching System (Solid Colours) – Madeira have a guide on how to convert this to (close) Thread Colours.

Before your job is Scheduled we will need your confirmed styles and numbers, once you provide these your job will be scheduled to print.

You can change these, however it will push your job out and a restocking fee may apply depending on what supplier we are using for your job.

It is best if you collate this and provide it once.

To proceed we need Proof approval and Final Quantity

Once these are provided your job is locked and loaded.

Before collection or courier we will requirement payment, we do have credit card options available.

If we are couriering the garments to you we will need a delivery address! Unless you are collecting.

We can do split deliveries, however there is a $10.00 per split (after the first address) fee – and additional courier fees.